Design Shape Optimisation

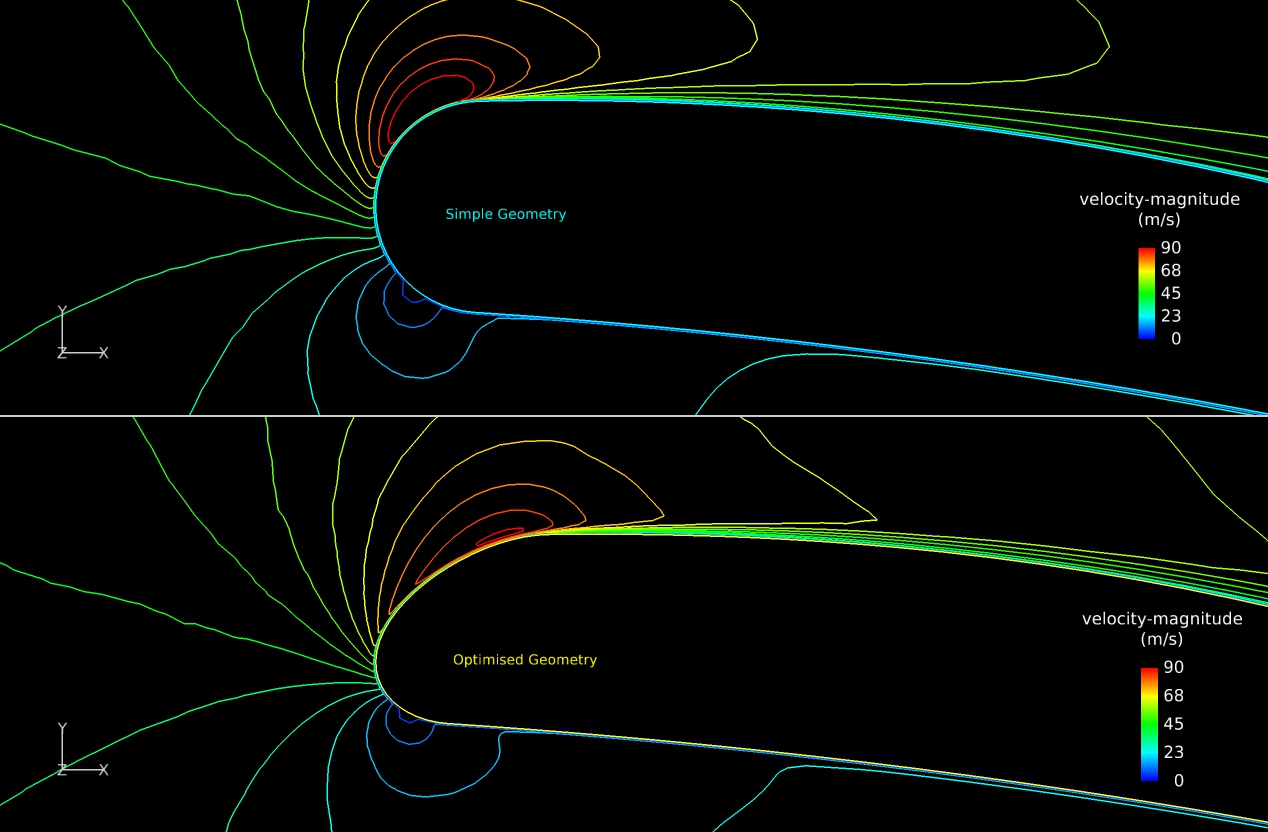

CFD is a great design tool and provides detailed insight into the characteristics of the fluid flow around objects or through equipment. Often the project objective is to develop a design that has a lower pressure drop, greater lift or reduced power. A powerful design tool that provides an efficient path to an optimised design is the ANSYS Adjoint Solver.

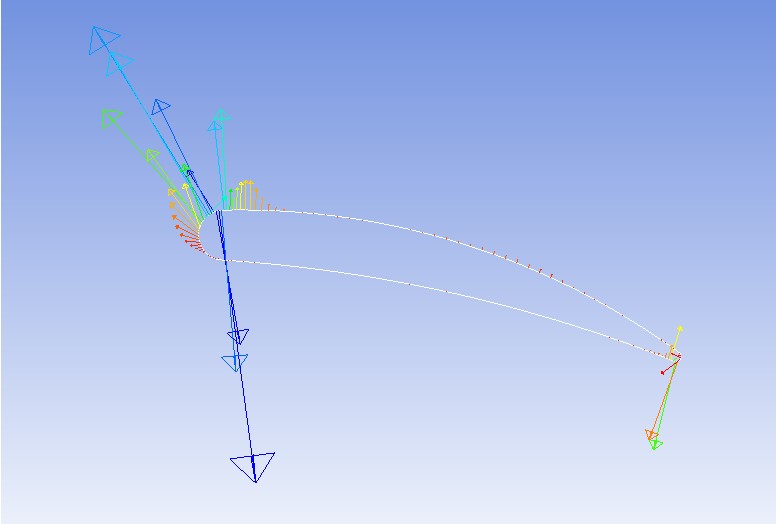

The Adjoint solver is used to compute the derivative of a chosen observation of engineering interest with respect to all the input data for the system. The solution provides guidance on the optimal adjustment that will improve a system’s performance.

The Adjoint solution can be used to estimate the effect of a change prior to actually making the change. Shape sensitivity data is combined with mesh morphing to automatically generate the revised geometry.

The optimisation objectives can include;

- Reduce drag

- Increased lift

- Reduced pressure drop

- Reduced swirl

- Reduced power

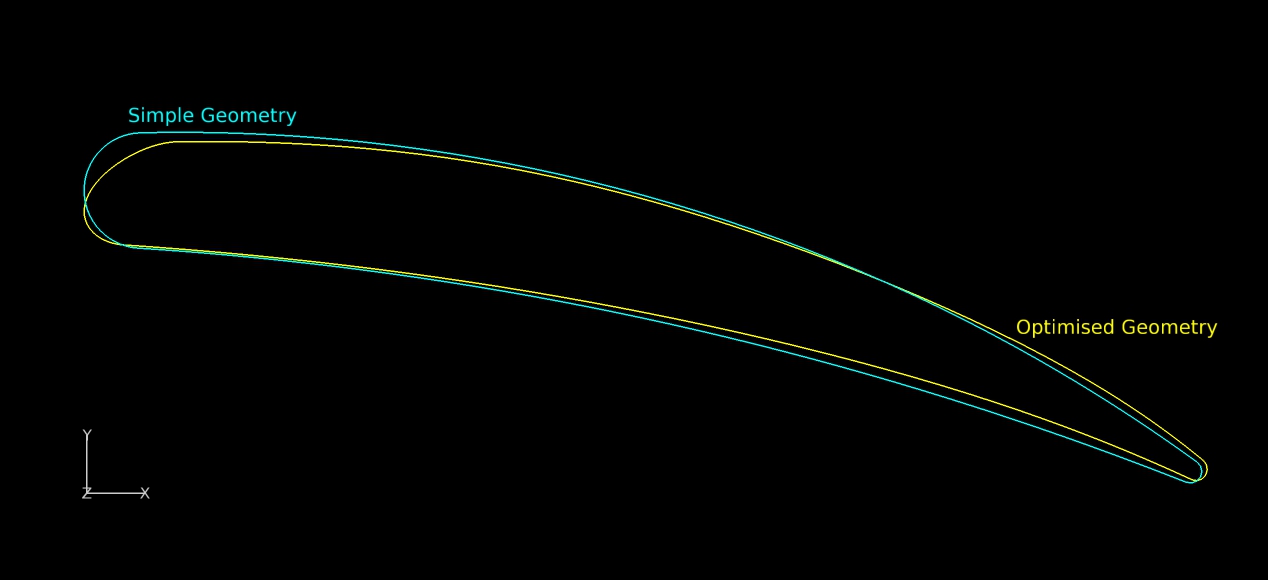

These objectives can be combined, for example an increase in lift can be developed while also reducing the drag. In the example illustrated here a simple aerofoil profile was generated with tangential fixed radius sections. Using the Adjoint solver the sensitivities to both the lift and drag were calculated. Then using the mesh morphing algorithm a revised profile was generated to provide a 10% increase lift combined with a 10% reduction in drag, achieved in just one design iteration.